Food Sector

Food Sector

Throughout our history we have maintained a strong presence in the food sector.

Health & Nutrition Sector

Health Sector

Rice n Shine offers innovative solutions for the Health & Nutrition Sector.

Dairy Alternative

Dairy Alternative

We ‘find the Rice Solution’ for plant-based consumers and those intolerant or opposed to animal-based ingredients.

Animal Feed and Petfood

Animal Feed & Petfood

Rice n Shine offers rice-based products, which contribute nutritional value in animal feed and petfood.

Agricultural

Agricultural

Rice n Shine stands for a brighter future through corporate responsibility and climate action.

Construction

Construction

As part of “finding the rice solution” we aim to reduce the ecological impact of construction.

Packaging

Packaging

The use & treatment of rice by-products gives numerous possibilities for industries, such as packaging.

Fuel & Energy

Fuel & Energy

Our Corporate Philosophy centers on increasing the value of by-products in the energy sector.”

Processing

PADDY SELECTION

- Our pursuit to offer one of the best basmati rice begins with seed selection.

- Each year we carefully select healthy and pure seeds.

- Throughout the season, an adequate network remains in place to interact with farmers from seedling to harvesting stage.

- Experts from Rice n Shine help to advise the required preparation of soil, use of fertilizers, pest control techniques and crop care.

- Comprehensive inspection & testing precede purchase of paddy lots.

- Random samples are drawn from paddy and tests are performed after processing to evaluate yield, grain length, field admixture and cooking characteristics.

- Paddy is purchased at the beginning of rice season that effectively eliminates all chances of mixing of inferior varieties.

Processing

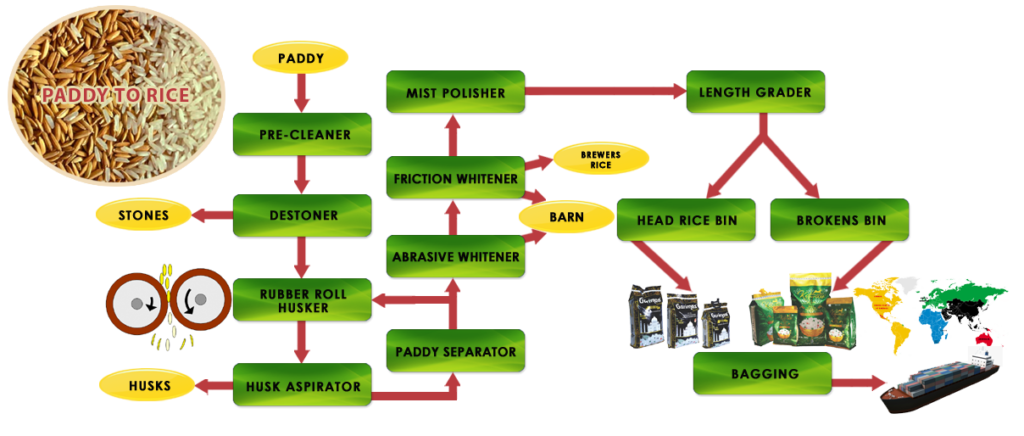

HUSKING

- The selected paddy is allowed to slowly reduce its moisture by a combination of modern and traditional methods until optimum moisture for husking is achieved.

- Gradual drying takes place to help avoid cracking in the rice grain.

- At the Rice n Shine Sheller brown rice is produced after cleaning, husking and grading.

- At this stage the outer husk is removed, leaving the germ and bran layer intact.

- Top-of-the-range machinery helps to ensure delicate rice grains maintain their form during husking.

We’re here to support you every step of the way.

Processing

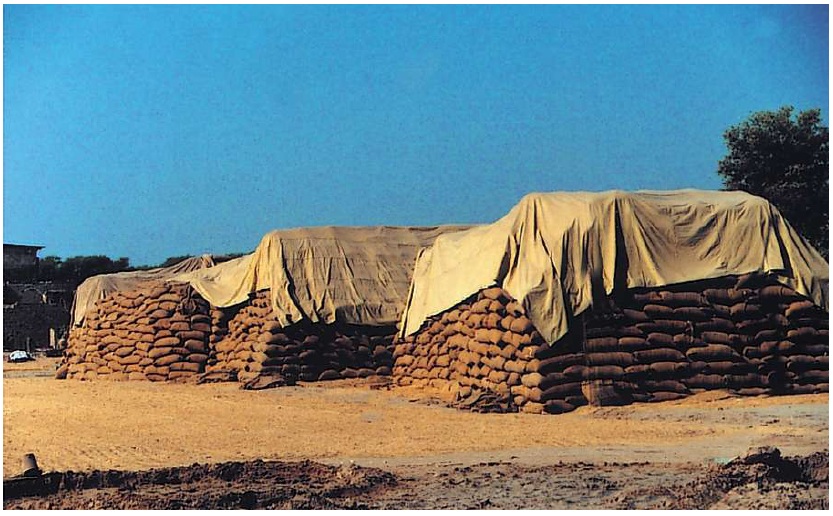

WAREHOUSING

- Basmati rice acquires optimal cooking characteristics and stronger aroma when matured over a period of nine months up to a year.

- It is therefore critical that the rice is properly matured before processing.

- Rice n Shine therefore has a strict policy of building up stocks during the harvest and carrying on with the maturation process under expert supervision.

- Well-ventilated and modern warehouse facilities have been constructed specifically for the storage of rice meeting food safety standards.

- During maturation our stocks are subjected to systematic inspection and control from time to time under experts’ supervision for the optimal preservation of rice grains.

Processing

WHITENING & POLISHING

- In the second stage of our processing the bran layers are removed through our advanced whitening and polishing machines that help to give our Basmati rice a pearl-white appearance.

- This process is carried out gradually over several phases to avoid the formation of cracks in our rice kernels.

- The number of phases depend upon the degree of whiteness required.

- Our modern mist polishers provide a uniquely clean and glossy appearance to the kernels of rice giving this technique a distinct advantage over traditional milling methods.

Processing

GRADING

- Our Basmati rice is graded at different stages on the basis of its thickness and length. Through this we ensure the removal of any irregular or broken rice grains from optimal grains.

- Advanced technology, such as Plan-sifters and Indented Cylinders employed at three different stages thereby achieving uniform grading.

We’re here to support you every step of the way.

Processing

COLOR SORTING

- Through this process we remove predominantly chalky and discolored kernels from our standard graded ones.

Processing

PACKAGING

- Rice n Shine operates computerized bagging systems to ensure the highest possible degree of accuracy in weighing.

- Several types of packaging materials can be used as per customer requirements.

- These include:

- Cardboard Paper-sack

- Polypropylene

- Polythene

- Cotton

- Jute

Our packaging process is designed and undertaken to increase the shelf life of products as well as easy handling until consumption.